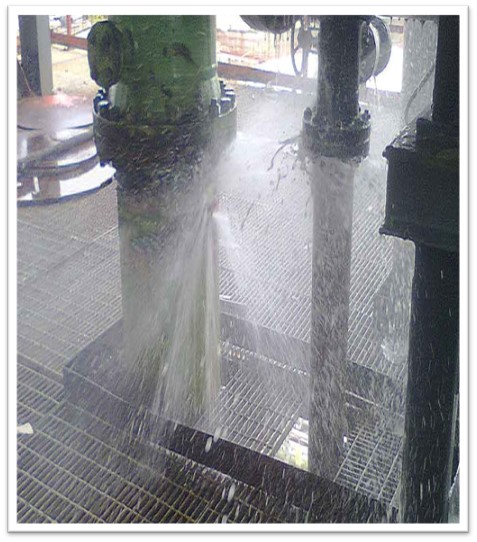

Super Speciality-Wrap Leakage Sealing Technique for Pipeline Leakage Sealing is now widely accepted in the Indian Oil & Gas Industry as a cost-effective repair alternative to traditional metallic materials.

A Pipeline leaking fuel oil can be repaired without taking isolation/shut down or draining of the pipeline. The Leakage Sealing work can be done at application pressure upto 10 kg/cm2 and temperature of not more than 80 deg C while applying.

Super Speciality-Wrap Leakage Sealing Technique process involves combination of Sealing Material, Engineered Polymers and Glass Fibre Composites Tapes designed to achieve the desired results.

Installation is straightforward, safe and fast and gives a repair that will outlast the 10 years life.

The Entire Application is done by our Team of Trained and Experienced Application specialists.

Super Speciality-Wrap Pipe Repair Technique for Leakage Sealing can be used on

- Leaking Pipelines

- Cracked pipelines

- Pitted Pipelines

- Corroded Pipelines

- Gauged pipelines

- Complex geometric shapes in pipelines; such as tees, wyes, elbows, or nozzles

- Sampling and instrumentation pipelines

- Restoring the Strength of a damaged pipe

- Reducing the strain in the damaged areas of the pipe by providing reinforcement and increased stiffness to the weak areas

- Providing a restraint so that leak can be stopped and does not increase

- Sealing the damaged area of the pipe from further development of corrosion

- Installation without disruption of production operation

- Light Weight. Does not add much weight

- Installed using Cold Work Technique

- Can be installed in Confined and Congested Work area

- Conforms to Complex Geometries

- Lower Total Project Cost

- Permanent Repairs

- Service Life of more than 10 years

Previous

Next